We will try to explain the work involved and what happens after a pattern is made. Checks that have to be completed of the sand mold and the core to ensure metal thickness is right in the void that is filled with metal. There are many other factors that have to do with castings like contraction, runner system, venting the core, metal temperature, speed the metal is poured into the mold, flow offs and riser sizes. We cant explain it all in the one post but have included some pictures to show you just some of the processes involved. A pattern that is used to make the external shapes of many of the Aussiespeed Performance Product may differ in size but the same amount of work goes into each and every product. The Aussiespeed pattern shown is what we call the top box, It is a Hemi 6 cylinder long runner manifold with the part number AS0089 it is a solid timber, plastic or aluminum shape that is normally in 2 halves. When a pattern is made you have to add contraction. A pattern has to be larger in size than what you want your final casting to be. Different metals have different contraction rate some are 1mm in 70mm some 1mm in 50mm and others 1mm in 100mm. An easy way to explain it is if a casting is 700mm long say a rocker cover the over all length could contract 10mm. You are thinking well thats easy we just make the pattern 710mm in overall length. Wrong the casting will shrink back to 700mm but every dimension changes. The distance between each bolt hole, the height, width, crossways depth the lot.

Note on top of the carby pad you will see a square block, it is the print and matches up to the print on top of the corebox. The dept on both pieces must line up to hold the core in the right place to give clearance or “wall thickness” to the job. It also locks in to the mold to hold it in position the same as the print bar on the ports.

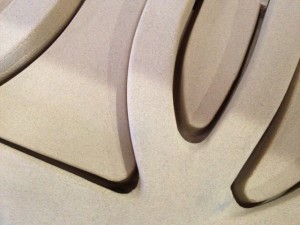

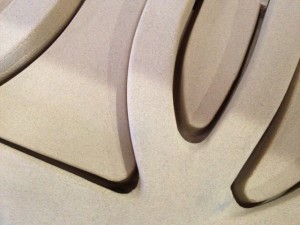

This is the sand mold that makes the outer bottom of the manifold, note the 2 large round holes, these are the locators that are a sand solid round shape that fit into the location holes to align the top and bottom of the pattern. When you look at a casting and see miss match on the out side it does not always mean that the internal doesnt line up as the internal core has its own location in the mold.

The locator is made on this Aussiespeed manifold from its own core box, The print that is in the sand mold must be exactly the same deepth and size to drop in to give perfect alignment of the top and bottom of the outside of the casting.

This is the core of the manifold, you can see the solid sand bar on the ends of the sand core. This print as it is called does 2 things, it is a locator for the front of the manifold ports so it can not move backwards or forwards and also makes the long legged core easier to handle.

With the core in position there is a print that locks the carburetor pad in place that also has to be set to the right height to give the correct gap to allow for metal thickness on the top of the external casting.

Its hard to tell from the angle that the photo has been taken but the gap you can see between the large outer sand mold and the internal “core” sand mold is where the aluminum flows to give you the casting.

Another picture of the internal core, it is because the manifold has an internal and external shape it allows us to make changes to the internal that have nothing to do with the outside shape of the manifold. So the port can have fins cast in the runner to boost velocity that simply can not be seen.

This was a trial fit and you can see the core has broken on the tie bar across the port face, the internal core has broken off sand which if it was cast would become areas of metal. There is so much more involved in making a manifold but we hope this gives you an idea of some of the processes.

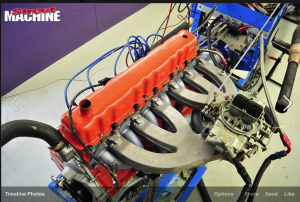

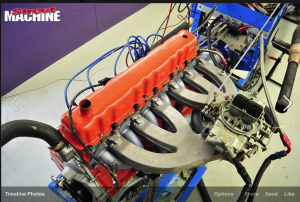

So after all the work and it is assembled with a runner system to allow the metal to get into the pattern and vents to let the gas get out this is what we are left with.

So after all that work we have a casting that the metal did not flow to all areas and we have a hole in the runner that is the second on the left and what we call flash which is the metal that is in the outside of the pattern.

So once you get the the tooling, runner system for the casting, make the machining fixtures then there is the hours of doing changes to the internal design and shapes on the ports and then its time to further improve performance on the dyno.

Be sure to check out the range of Aussiespeed manifolds in our online store. To View Our Range Click Here